Complete CNC Tooling Solutions

TNT Motion delivers high-precision CNC clamping tools that meet the demanding requirements of modern machining centers.

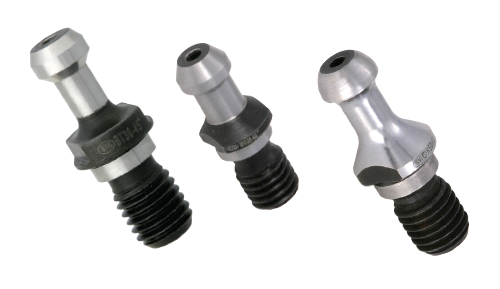

Our comprehensive range includes precision collets, pull studs, clamping nuts, and toolholders manufactured to

exacting European standards while offering competitive pricing through our optimized supply chain.

Whether you operate high-speed machining centers, multi-axis CNC mills, or production turning centers,

our clamping tools ensure secure tool retention, minimal runout, and consistent performance

throughout extended production runs.