Technical Support and Added Value Services

Our team delivers European engineering bearing support—design reviews, diagnostics, and preload tuning—so distributors can trust every cost effective China bearings shipment we certify.

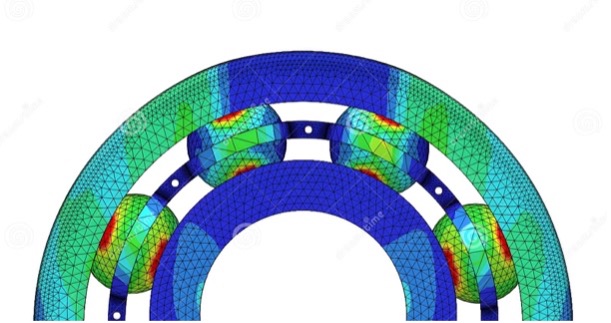

Bearing Life and Fatigue Calculations

In applications where precise dimensions are critical, we provide consultation services to ensure the selected bearing dimensions align with the mechanical and load requirements of the system

Field Return Analysis

Our team has an extensive experience in field return analysis. Whatever happened to your bearings we can find it out

Lubrication Analysis

Selecting the right lubricant is critical for maximizing bearing performance and service life. Our lubrication analysis service evaluates grease compatibility, oil viscosity requirements, and contamination resistance to ensure optimal protection under your specific operating conditions including temperature extremes, high speeds, and demanding load cycles.

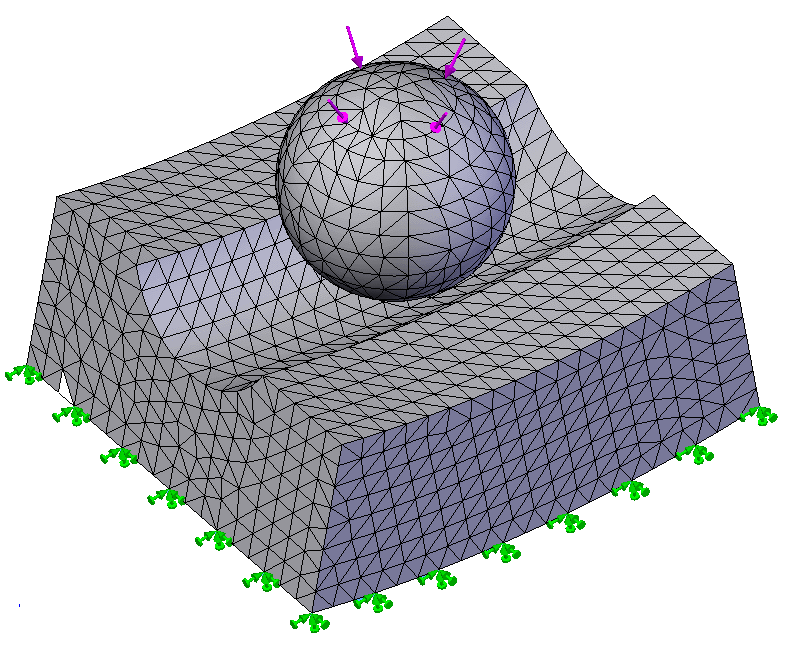

Clearance Reduction and Mounting Interference Calculation

Proper fitting is crucial to prevent premature failure. Our fitting calculation service provides precise recommendations on tolerances, fits, and adjustments tailored to specific operational requirements. With the correct mounting conditions, clients can avoid common issues such as misalignment and improper load distribution, ensuring longer bearing life and smoother operation.

Frequently Asked Questions

What Clearance Should I use in my application

Clearance depends in the fitting of the bearing if the bearing is press-fit with high interference it will require high initial clearance

What bearing quality do I need?

Typically very highly loaded applications or high speed applications that stress bearings to the limit need very low vibration level (Z3V3) and possibly special greases and special filling rate

My bearing if vibrating what shall I do?

There are vibration analysis that can be performed without dismounting or even stopping the bearing. These are frequency vibration analysis. However they require special accelerometers and vibration analyzers

Is Standard grease enough for me?

Standard greases are fine for most of the applications. In case the bearing is heavily loaded, is working at high speed or temperature, a specially designed grease might be required. That does not necessarily mean more expensive grease.

Partner with TNT Bearings for wholesale bearings for distributors supported by Italian engineers and a reliable OEM bearing supplier workflow in China.

Got more questions?

Feel free to reach out.